Email Us

sales@global-ams.com

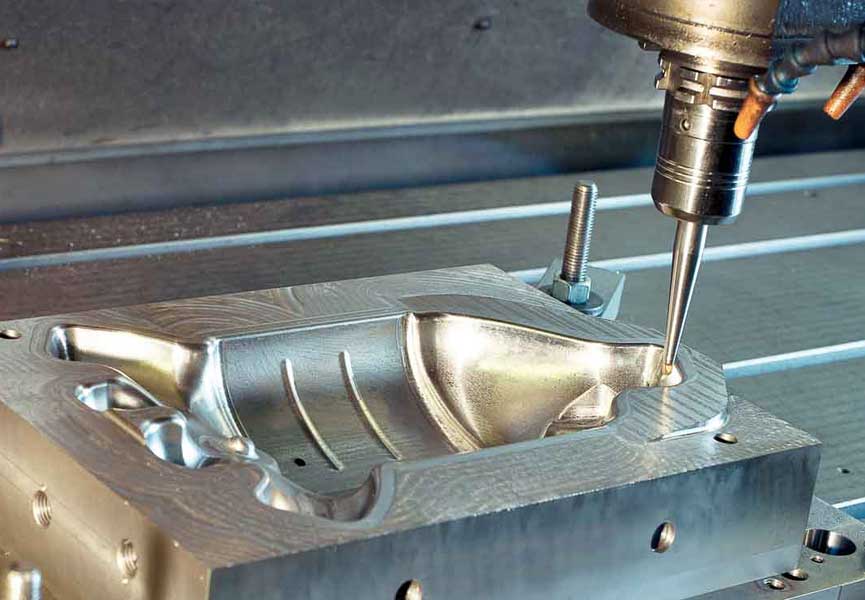

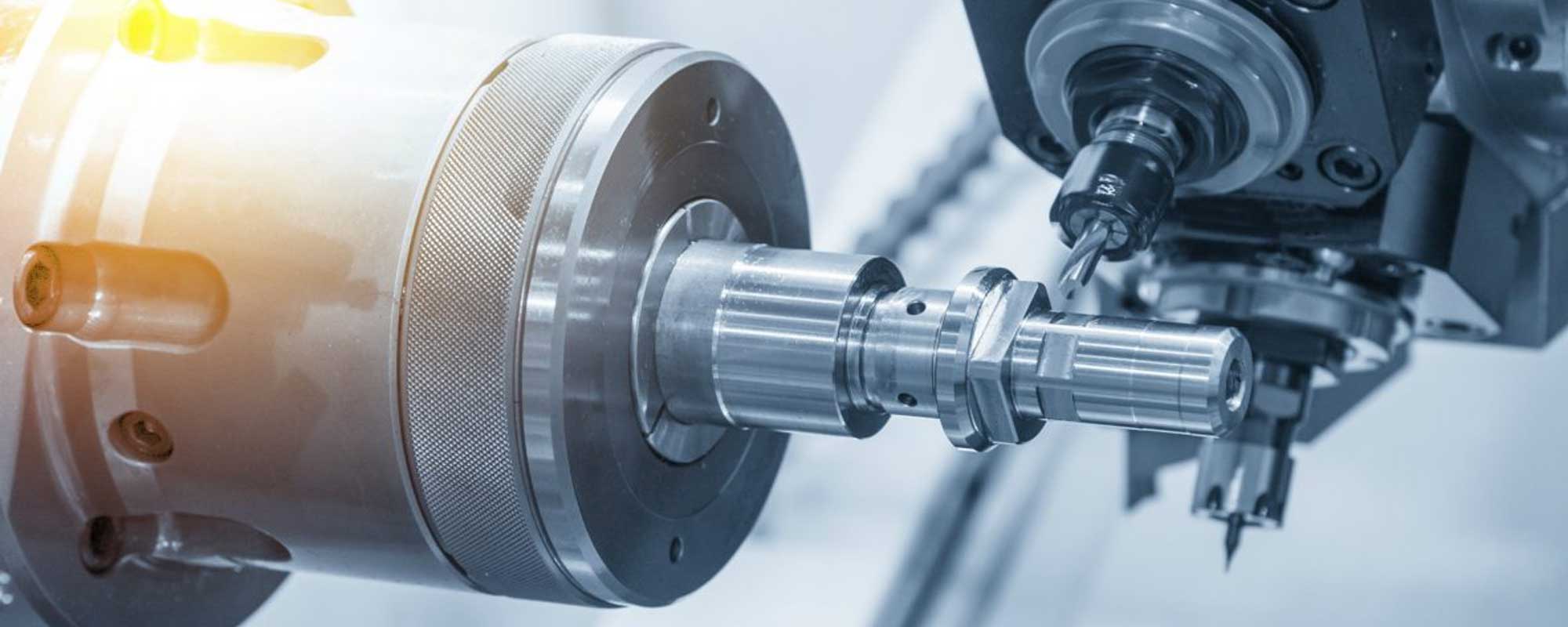

MACHINING

Combined with our cutting, grinding, lapping and polishing capabilities, our machining centers enable us to offer vertically integrated solutions that shorten production times for difficult to machine components.